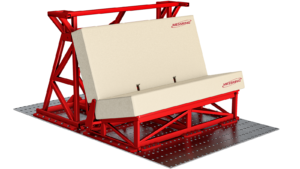

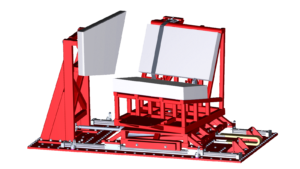

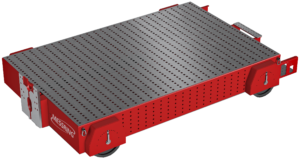

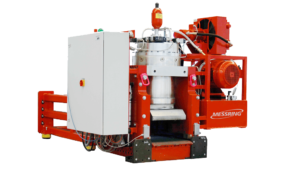

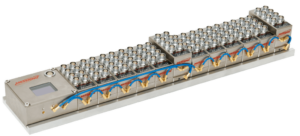

Passive Safety

We make the mobile world safer.

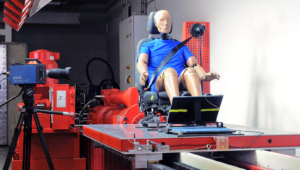

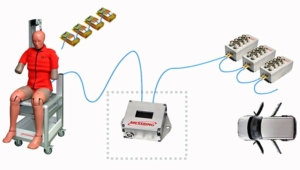

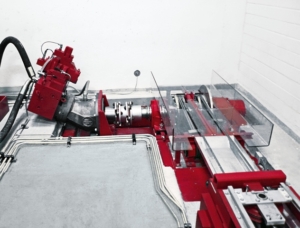

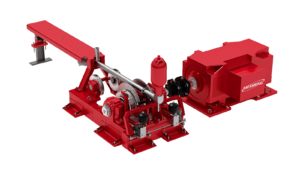

With innovation, precision, quality and customer focus, MESSRING support companies in developing even safer vehicles and modes of transport and in guaranteeing the high demands of active and passive vehicle safety.