In the first session, our lighting experts have already explained how lighting systems at MESSRING are planned for crash or sled test facility operation and the particular advantages of applying M=LIGHT LED lamps. We have asked Max, Stefan, Benjamin and Justinas again for an interview. This time we wanted to find out why these high amounts of light are necessary at all and what exactly the point of “flashing” and synchronizing flash and camera is.

Why is so much light needed at all when shooting crash tests?

Max: Who likes to be in the dark? – No, joking aside, the high amount of light required is a result of the special demands of high-speed recordings. You have to understand how cameras work. The amount of light incident on the camera sensor is controlled by the width of the aperture and its exposure time. When the aperture is wide open, a lot of light can reach the sensor, but the image becomes blurred, and at the same time moving objects blur at longer exposure times. Both of the above are very bad in crash test shots, which are taken for measuring and evaluation purposes. In order to obtain usable high-speed film material, short exposure times with small aperture are required. This is only possible with large amounts of light, which we can generate with M=LIGHT LED, for example.

So the more light there is, the better the camera can work?

Stefan: In principle, the better the illumination, the better the results that cameras can achieve. With the M=LIGHT LED we can in steady mode already generate a reliably high luminous flux of 75,000 lm in daylight range and in flash mode – i.e. flashing at up to 25,000 fps – we can even increase this to 150,000 lm with the same energy consumption. Thinking the other way round, in flash mode only half the number of lamps is needed to achieve the same brightness. We already explained which solution makes sense and how it is elaborated in the last interview.

For good results it is important that the illumination is available at the right time, exactly when the camera exposes the sensor. But how this works is better explained by Justinas, it is his area of expertise.

In principle, the better the illumination, the better the results that cameras can achieve.

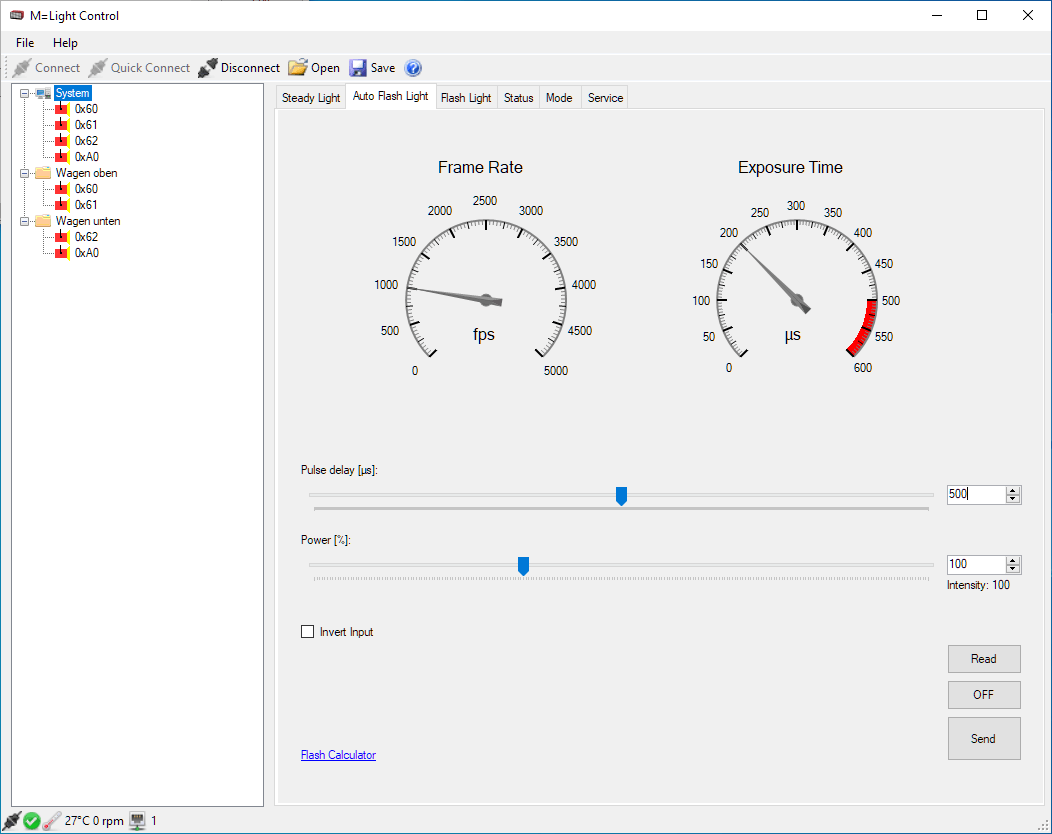

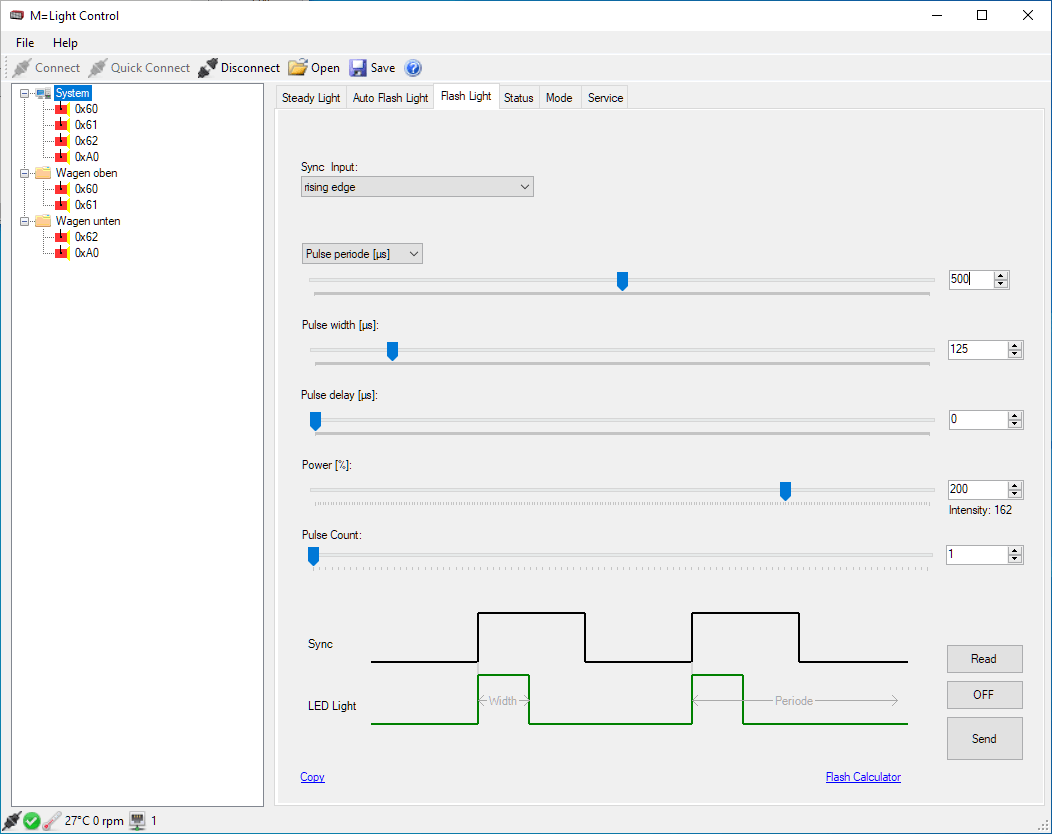

Justinas: Thank you! State-of-the-art cameras in high-resolution range now also work with high-frequency shutter speeds, up to 4000 fps are no longer unusual. To ensure consistent exposure of the images without visible fluctuations at these high frame rates, a microsecond precise synchronization of flash and camera shutter speed is absolutely necessary. The M=LIGHT can be adjusted to the camera needs and flashes exactly the fps that are required.

That sounds demanding, how does this synchronization work?

Justinas: With the right tools, it’s actually quite simple. We prefer to use our high-frequency M=SYNC communication infrastructure, where timing and triggers are distributed digitally, interference-free and precisely at the speed of light via fiber optics. This makes networking cameras and various lighting units simple and easy. The light is then controlled centrally and together with the other test operations using our Crashsoft software from the control station. This is a great advantage, especially for large-scale facilities.

Benjamin, now that your colleagues have already explained everything we wanted to know, you have a few closing words for us?

Benjamin: Hm, there’s not much to add. Perhaps one more thing – the M=LIGHT LED can deliver its output 24/7 and has already proven its practical suitability in numerous applications.