With M=BRAKE, MESSRING launches the world’s first solution to add the forces of Automated Emergency Braking into a crashtest facility, reproducing dummy and vehicle dynamics prior to impact.

Modern crash test facilities must simulate crash situations realistically and with high precision. In order to meet this requirement, they need to be able to keep up with changes in the general traffic situation such as new drive and mobility concepts as well as with the further development of automotive technology. Take for example onboard active brake assistants and electronic early warning systems, which are effective in reducing the severity of many frontal collisions. Crashes in which the brakes are not applied are increasingly becoming the exception rather than the rule. Tests for vehicles, restraint systems, and other safety components therefore need to be adapted to accommodate this new reality. For this purpose, MESSRING is launching an urgently needed innovation: The M=BRAKE. This new pre-braking system for crash test facilities is able to run pre-defined braking profiles in sled and vehicle tests with a high degree of precision and reproducible results. It’s the world’s first subsystem that recreates the intervention of brake assist systems prior to an actual crash, integrating it into the crash test run. The driver’s braking maneuvers can also be individually simulated with little effort.

The M=BRAKE is designed for sleds and vehicles with a total weight of up to 5,200 kg, a max deceleration of 0.8 g as well as maximum speed of 100 km/h. Braking maneuvers and pre-crash braking scenarios can be individually defined and entered via MESSRING’s CrashSoft control software. Car-to-car tests with rear or frontal impact can also be carried out without any problem.

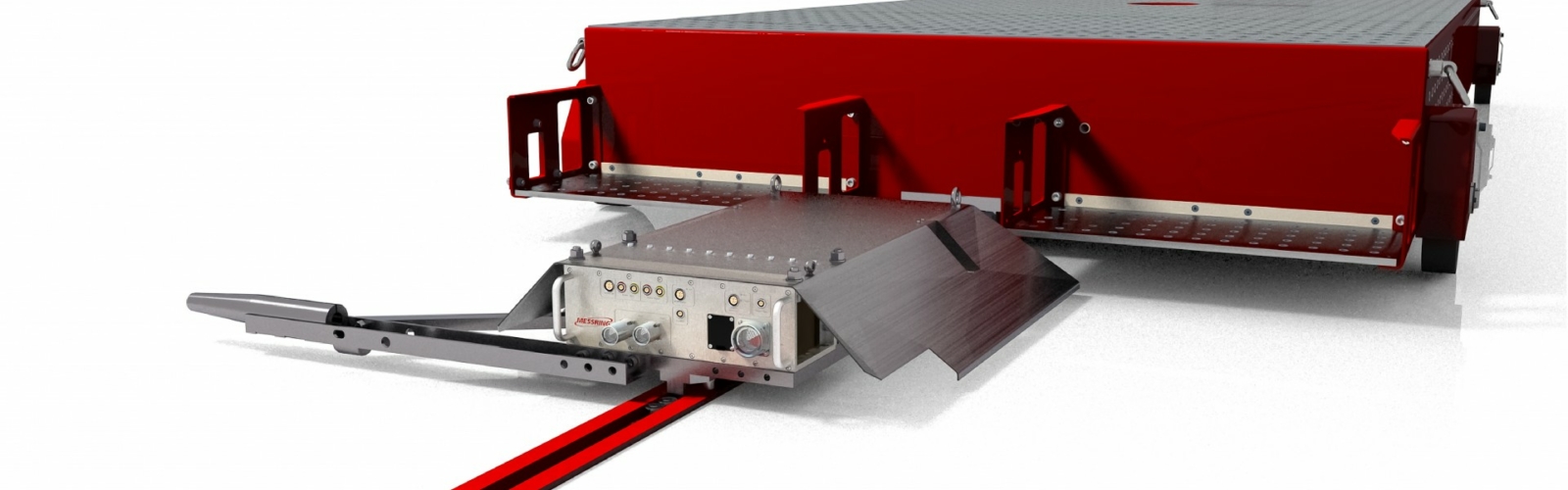

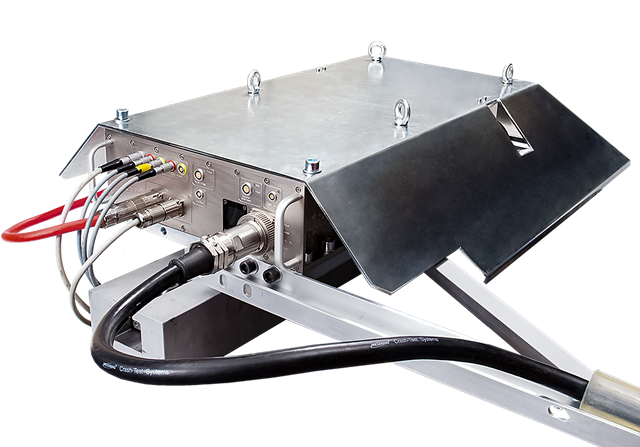

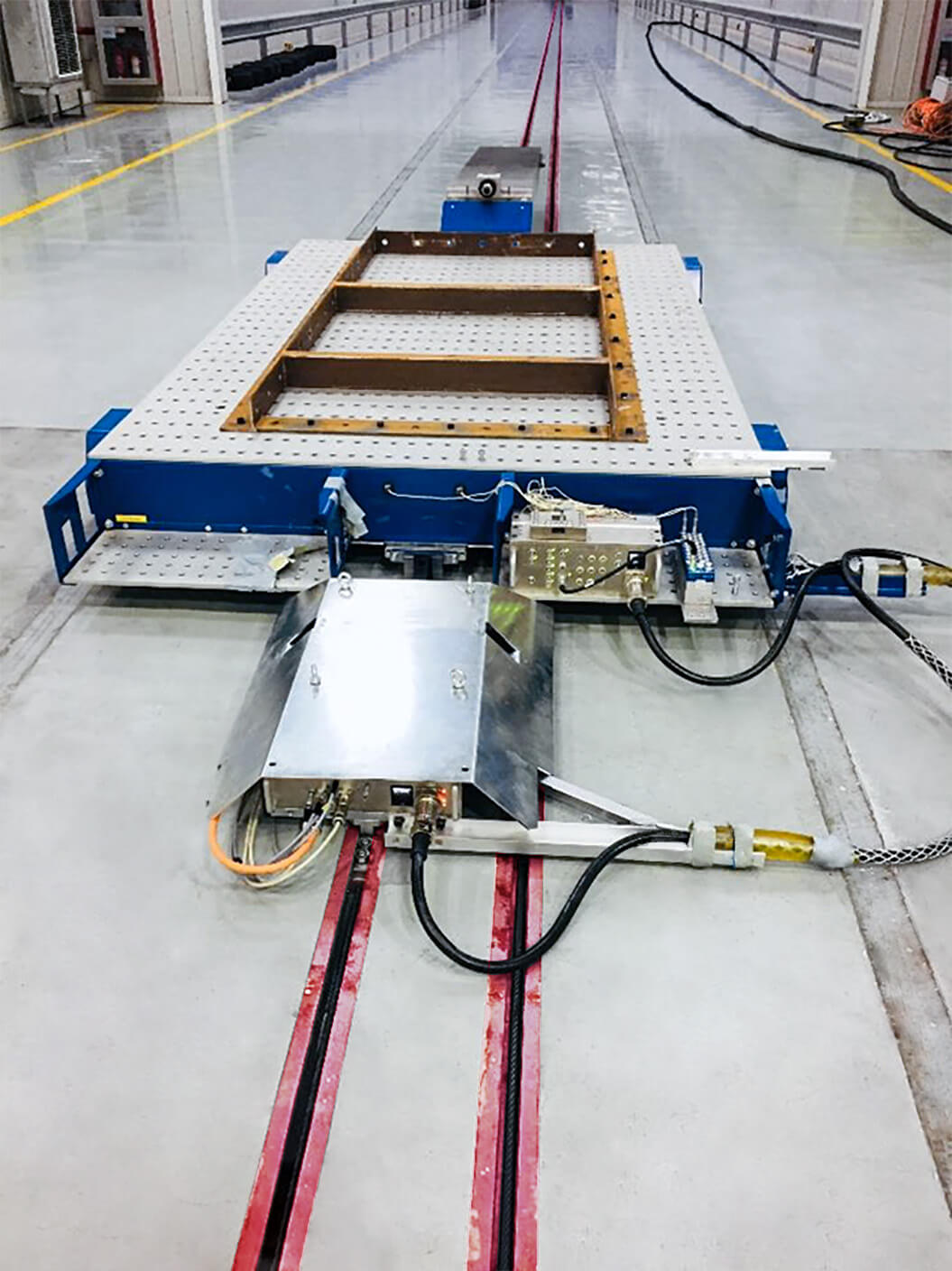

M=BRAKE can be easily added to a MESSRING’s MicroTrack equipped crash test facility without any downtime. The M=BRAKE is connected to the vehicle or sled and pulled along like a trolley in the crash test facility’s MicroTrack. M=BRAKE receives signals via a trailing cable from CrashSoft, where the pre-programmed braking profiles are stored. A hydraulic unit on the M=BRAKE trolley generates the corresponding pressure (up to 150 bar). A total of 16 brake cylinders on the M=BRAKE press the brake pads up against the inside of the MicroTrack, providing the necessary brake pressure and decelerating the vehicle or sled as specified.

“The M=BRAKE allows you to brake as defined with much more accuracy than it was possible in the past,” says Dierk Arp, Managing Director of MESSRING. “That brings the corresponding test runs a decisive step closer to the reality on the road.” Vehicle pitching before a collision, resulting from emergency braking, for example, can thus be recreated, along with changes in the position of the dummy, its head, torso, and legs. In addition, pre-crash braking has an impact on seat belt tension, the vehicle interior or even on child seats.

“We developed the M=BRAKE in response to a need in the automotive industry. There is currently an enormous demand for solutions that help integrate active safety systems such as the active brake assistant into classic passive safety crash tests,” explains Dierk Arp

The fact that various M=BRAKE systems have already been sold to facility operators in Germany, China, and Canada demonstrates just how large the demand is.